When it comes to printing t-shirts, your two main options are digital and screen printing. And while you may think digital printing is the better choice, it’s important to understand that there are also benefits attached to screen printing. To help you figure things out, we thought it would be useful to put together a brief article about this subject. If this is something that you want to learn more about, read on as we break down everything you need to know about screen printing for t-shirts.

What is Screen Printing?

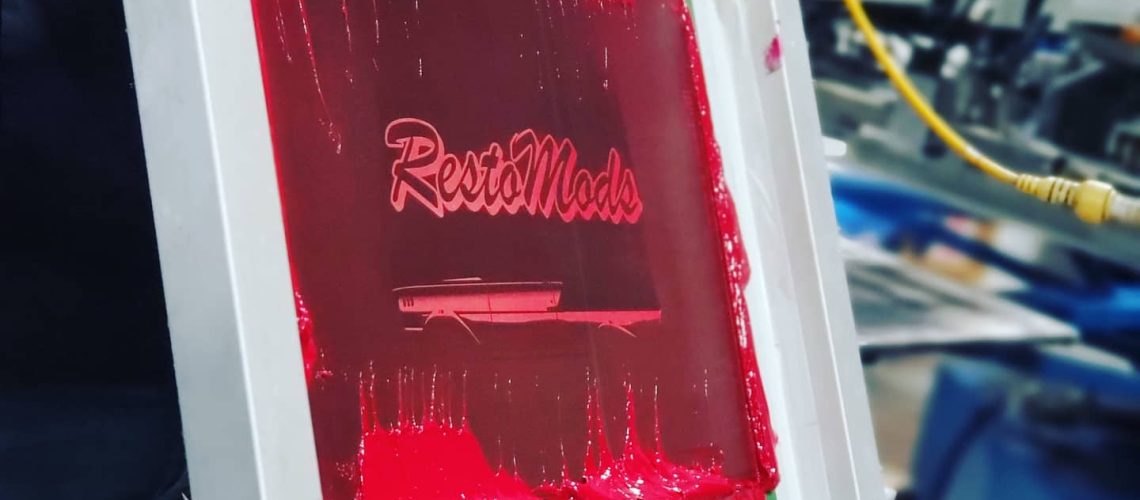

Screen printing is a printing technique where a mesh is used to transfer ink onto a substrate, usually paper, cloth, or metal. The ink is forced through the mesh by a squeegee, leaving a design on the substrate. The screen printing process has been around for centuries, but it was first adapted for commercial use in the early 1900s. Since then, it has become one of the most popular printing methods, thanks to its versatility and affordability. Screen printing is used for a variety of applications, including t-shirts, posters, signs, and decals. The process is relatively simple and can be done by anyone with a little practice.

How Does Screen Printing Work?

The screen is placed on top of the shirt, and then ink is placed on top of the screen. A squeegee is then used to spread the ink evenly over the screen. Once the ink is evenly distributed, the screen is then removed, and the shirt is placed in a dryer to set the ink. The screen is then placed on top of the fabric and then ink is pushed through the screen using a squeegee. The ink only goes through the open areas of the screen, which creates the design on the fabric. After the screen has been created, we need to do a few things to get it ready for printing. This process takes a bit longer than a digital print because everything has to be done by hand.

The ink is mixed in the color laboratory to get the exact colors that the customer wants. The inks are also very thick, which makes the design stand out. The inks used are usually thicker than those used in other printing techniques, which results in a design that is more visually “pop” in terms of color and thickness.

The press is a large metal tool that is used to create orders. It is very heavy, and it is shaped like a circle. There are twelve arms on the press that have a flat surface. This is where the wooden silk screen is placed. It is like a one-person assembly line where one shirt is created, and then the wheel is turned to the next blank t-shirt.

The screens are lowered onto the t-shirts. The ink is then poured onto the shirts, and use a rubber squeegee to quickly move the ink from one end of the shirt to the other. As the ink moves over the screen, the corresponding areas on the shirt will soak up the ink. Depending on how many colors are in the design, you may have to take each shirt and perform the process multiple times. After the ink is completely applied to the shirt, it is placed on a conveyor belt that runs under a heat source. This dries the ink and sets it into the shirt permanently.

How Does Screen Printing Differ from Digital Printing?

Digital printing and screen printing are two popular printing methods used for a variety of applications. While both methods can be used to produce high-quality prints, there are some key differences between the two that you should be aware of.

Screen printing is a more traditional printing method that involves creating a stencil of your design and then using that stencil to apply ink to your substrate. This method is typically used for printing on t-shirts, posters, and other flat surfaces. One of the advantages of screen printing is that it can produce prints with a high level of detail.

Digital printing, on the other hand, is a more modern printing method that uses digital technology to transfer your design onto your substrate. This method is typically used for printing on more diverse substrates, such as fabric, wood, metal, and glass. One of the advantages of digital printing is that it is a more versatile printing method that can be used for a wider range of applications.

Why is Screen Printing Good for T-Shirts

There are many reasons why screen printing is good for shirts. One reason is that it is a very versatile printing method. Screen printing can be used on a variety of different fabrics, including cotton, polyester, and nylon. This means that you can use screen printing to create shirts in a variety of different styles and sizes.

Another reason why screen printing is good for shirts is that it is a very durable printing method. Screen printing is not susceptible to fading or peeling, which means that your shirts will last for a long time. Additionally, screen printing is resistant to water and other chemicals, which means that your shirts will stay looking new wash after wash.

Finally, screen printing is good for shirts because it is a very affordable printing method. Screen printing is less expensive than other printing methods, such as digital printing. This means that you can get high-quality shirts without spending a lot of money.

Conclusion

We hope this article proves to be useful when it comes to helping you further your understanding of the screen printing process and why it’s great for t-shirts. Through screen printing, you’ll be able to achieve unique and high-quality prints for your t-shirts. Be sure to keep everything you’ve learned here in mind so that you can make the most informed decisions when producing t-shirts.

If you’re looking for high-quality screen printing services, then you’ve come to the right place. Alive Print Shop provides quality embroidery, custom clothing, and screen printing. For more information, get in touch today!